Godwin Manufacturing specializes in steel dump bodies, platforms, truck hoists, and rollback car and equipment carriers.

Learn More

Learn More

America's Premier Truck Equipment Manufacturer

Godwin Manufacturing specializes in steel dump bodies, platforms, truck hoists, and rollback car and equipment carriers.

Learn More

Learn More

Galion-Godwin specializes in manufacturing steel and stainless steel dump bodies and hydraulic hoists.

Learn More

Learn More

R/S-Godwin specializes in manufacturing custom class 5 - 8 steel and aluminum dump bodies.

Learn More

Learn More

Williamsen-Godwin specializes in steel and stainless steel dump bodies, pup trailers, and water tanks.

Learn More

Learn More

Champion specializes in conversion, underbody, direct mount, telescopic, and trailer conversion hoists.

Learn More

Learn More

Allied specializes in both simple, and advanced mobile hydraulic systems for the dump truck and snow removal industries.

Learn More

Learn More

Family owned and globally known, Godwin Manufacturing Company started from humble beginnings.

Pat Godwin came home from work and told his wife, Judy, that he had delivered his last case of soft drinks as a route salesman for Pepsi Cola. Judy yelled, "April Fools!". Pat said, "It may be April fools Day, but I will not be going back". They had two toddlers in diapers at that time. Realizing he had quit a good, steady job, Judy cried for weeks. Judy had a job as a cashier at a local grocery store. When she left for work each day, Pat would unplug the electric stove and plug in his welder that was situated in a detached 18' x 22' garage.

Godwin quickly increases sales and its workforce. As business picked up, Pat decided he needed help and more space. With approximately 10 employees and a rented 80' x 80' building, Godwin Welding Service was formed. (Top right: Pat Senior. Bottom right: Pat Junior. Third from top right: Godwin Legend and longtime plant manager Larry Clark.

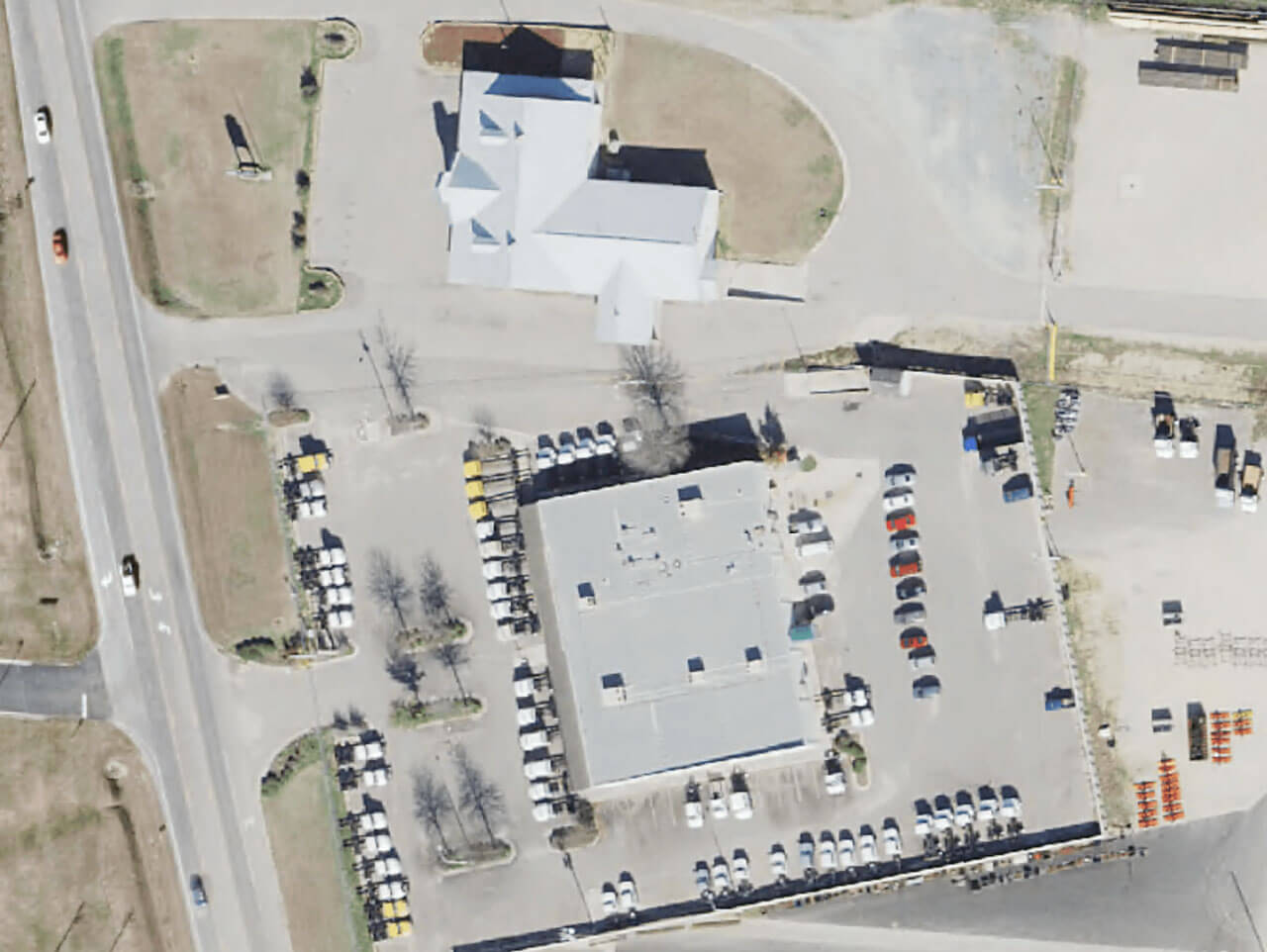

By August of 1976, the small start up business had outgrown the rented building and was moved to it's current location on Hwy 421 in Dunn, NC. It was also around this time that Godwin began manufacturing hoists in addition to bodies. This would be Godwin Manufacturing's permanent location.

In 1979 Godwin Welding Service officially became Godwin Manufacturing Company Inc. The change was a final result of a long transition from general welding services to specific manufacturing. Increasing demand for quality platforms and dump beds in the local area drove the change. As a newly incorporated company, Godwin's primary focus was on truck equipment.

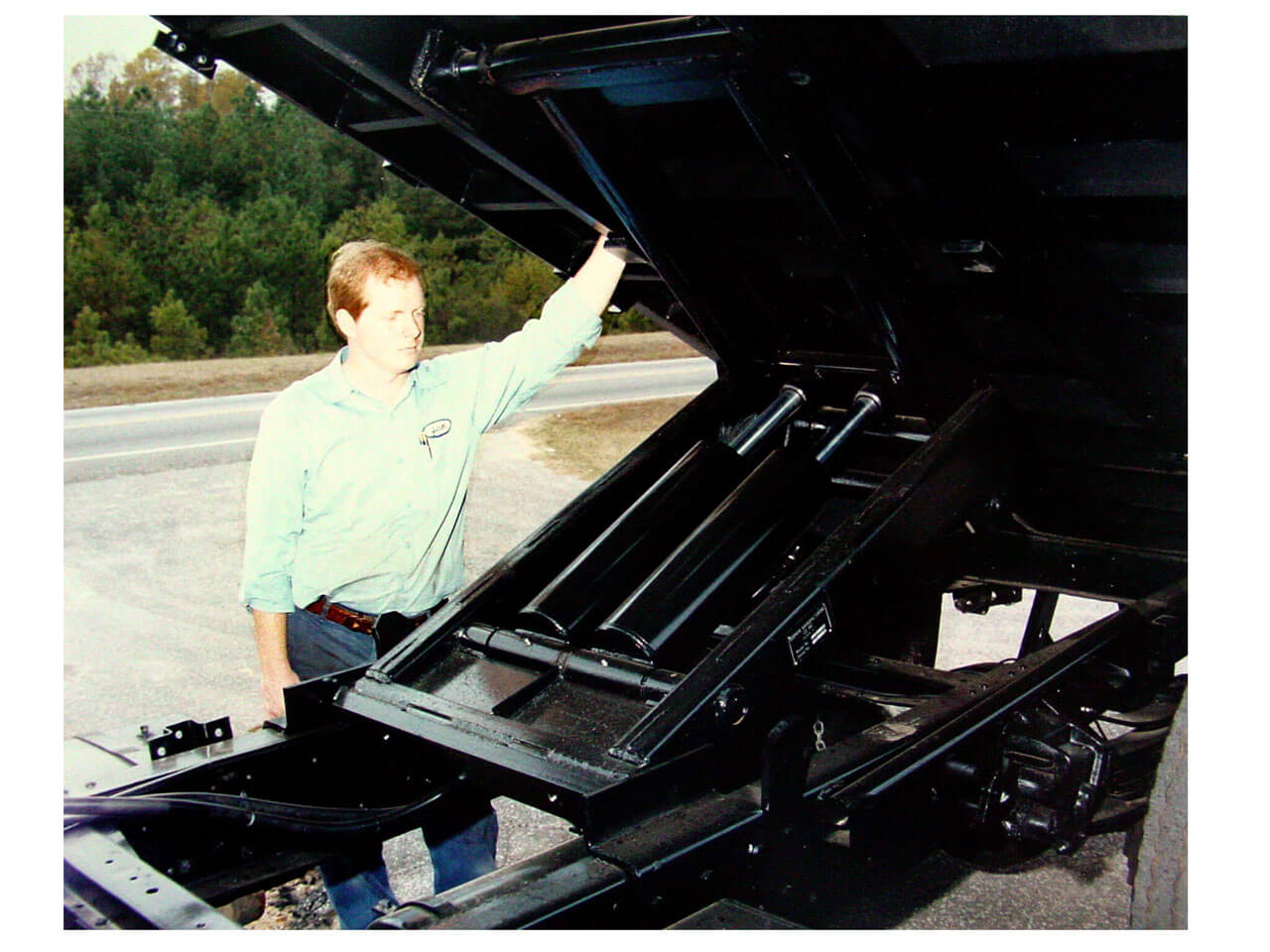

In 1980 Godwin began manufacturing their own hydraulic hoists after becoming dissatisfied with the overall value of purchased units for use under their equipment. It was a general belief that "we can do it better" that drove the investment into the new hydraulics division expansion of Godwin. This newly added division designed, tested, and manufactured nearly all of the non-telescopic hoists used under Godwin bodies. These products would later take a life of their own and birth one of the largest hoist manufacturing companies in the country.

Throughout the mid 80's to late 90's Godwin manufacturing experienced tremendous growth. Popularity of their quality products at affordable prices exploded throughout the mid atlantic states. The company was no longer a local manufacturer, but rather a regional staple in the truck equipment world after aggressively winning multiple state municipal contracts.

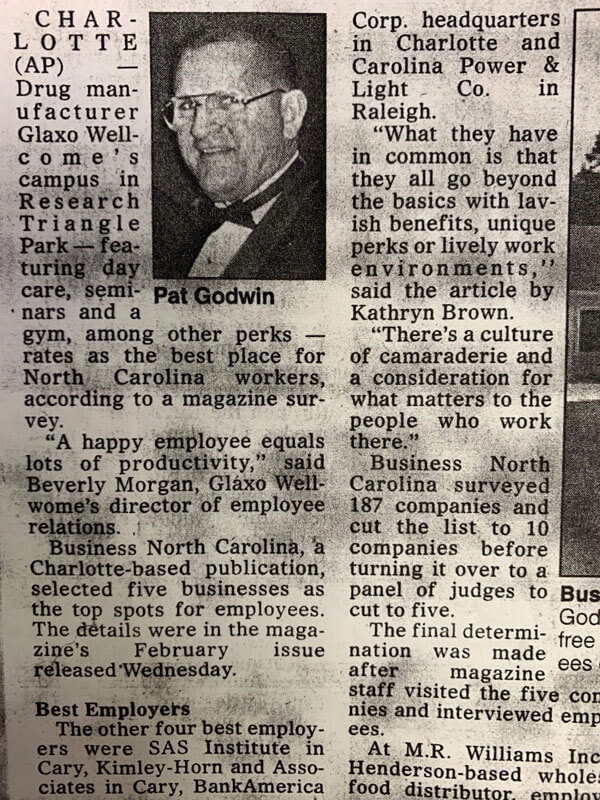

In 1998 Business North Carolina Magazine named Godwin Manufacturing a Top 5 Employer in the state. Such a distinction is rare for an industrial manufacturer. Many factors were considered for the award. Most heavily were the state of the business and overall quality of benefits and services offered to employees. For perspective on significance, Bank of America, SAS Institute, and Glaxo pharma were some of the other winners.

Substantial growth can cause some problems. One of Godwin's biggest problems was a bottleneck in production caused by an overloaded pant shop. Pat decided the solution would be powder coating. Godwin built a state-of-the-art, one of a kind, fully automated paint facility. When completed, it became one of the largest of its kind in the world. Not only did the facility completely eliminate the bottleneck, but it further increased the overall quality of the final product with an industry leading coating.

Pat acquired R/S Truck Body in Ivel, KY. R/S had been building bodies for the coal industry since 1968. There were some similarities in products but also enough differences to expand the market for both companies and make them stronger. R/S also brought aluminum bodies into the mix. This would be the first of many more successful acquisitions.

Barely a year passed when Pat had another great opportunity. This time it would be the purchase of long time competitor McClane Galion Dump Body in Winesburg, OH. Galion originally began in the 1870's as Galion Buggy Company. This purchase was sweetened by the fact that many years before, Galion had attempted to purchase Godwin. By September 2003, Galion became part of the Godwin family, further strengthening the Godwin presence in the industry. It is now called, Galion-Godwin Truck Body Company.

After the addition of R/S and Galion, The Godwin Group was created to streamline and centralize accounting, purchasing and marketing for all companies. This solidified the companies into one while still allowing each to maintain their unique and valuable qualities they became known for.

The companies were not only successful at building quality dump bodies, the hoist business was growing more popular as well. It was time for yet another expansion. This time the answer was just across town. The 250,000 square foot building which once housed Champion Sportswear was available for purchase. This facility was perfect to house the Godwin Hoist business and corporate offices. In early 2004, Champion Hoist and Equipment was formed and settled in to the new location. Today Champion produces over 25,000 hoists per year.

Godwin had considered going into the plow and spreader business many times over the years but had been highly satisfied with the products they had been receiving from Good Roads and decided against manufacturing their own. Godwin Manufacturing was the largest distributor for Good Roads so when then owner decided to sell the company, it seemed like the perfect fit. Once Pat Jr was convinced he was serious about selling Good Roads, the plan to relocate the Indiana company to Dunn, NC was put in place. The Godwin Group was officially in the snow equipment business! Good Roads, founded in 1887, is credited as the originator of the modern snow plow and was the first to put a plow on a motorized vehicle.

In spring 2014, another opportunity caught the eye of the Godwin management team. Tesco Williamsen Manufacturing in Salt Lake City, UT was available for purchase. While the team had been looking to move westward, they were not convinced this was the right opportunity. Once the team met with the wonderful Williamsen staff their minds were changed. Before the team headed back to NC, they made a verbal agreement that saved the company from closing the doors and sending everyone home. Thirty days later, Williamsen was officially part of the Godwin family.

Allied is the new branding of a central hydraulic system started by Godwin in 1984. Allied specializes in both simple, and advanced mobile hydraulic systems for the dump truck and snow removal industries. Management saw opportunity in mobile hydraulics after the industry became stale with bulky, over complicated systems that were developed without substantial user input. After selling and installing many thousands of 'Godwin' systems, and installing thousands of other brand systems, the experience and knowledge made the expansion easy.

What started as a welder in a small backyard garage has now grown into the largest family-owned and operated truck equipment manufacturer in the U.S. One man's vision has turned into a family business. With 3 generations working at the company, it is not just a job, it is a life investment that will carry on and grow for many years to come. Who knows what the future holds for this innovative company and the man that started it all...

We build our company on quality products and superior customer service.

With The Godwin Group, business is a family affair. Distributors, Operators and employee are our extended family and we treat you as such. Allow us to introduce ourselves...

From the way we operate our company, to the unique and innovative products we offer, Godwin is NOT your average truck equipment manufacturer. We are structured to provide superior value.

Interested? Read moreExplore our huge product distribution and installation network, and purchase our products at a convenient location near you. These companies obviously know a thing or two about quality and service.

Find a distributor or interested in becoming a distributor? Get in touch